At Precision Fabrication & Laser Cut, we specialize in providing high-quality pipe support fabrication solutions tailored to meet the unique needs of diverse industries in Canada.

Our experienced team utilizes cutting-edge techniques and materials to engineer reliable and efficient pipe support fabrication services that adhere to industry standards and client specifications. Whether you require custom pipe support fabrication for oil and gas, industrial, or construction projects, we deliver excellence at every step.

Pipe Shoes

Pipe shoes are essential support components designed to cradle pipes and protect them from direct contact with structures, reducing wear, heat transfer, and corrosion risks. They are commonly used in high-temperature or insulated pipelines.

At Precision Fabrication & Laser Cut, we have successfully fabricated a wide range of pipe shoes for industrial, petrochemical, and energy projects across Canada. Our expertise ensures each shoe is precisely built to withstand the specific load and environmental conditions of your system.

Pipe Clamps

Pipe clamps provide secure, adjustable support by fastening around pipes to hold them in place while allowing for some controlled movement if necessary. They are widely used in mechanical, industrial, and utility piping systems.

Our team has extensive experience producing heavy-duty and specialized pipe clamps, including insulated and high-load variants. Each clamp is fabricated with precision to meet exact pipe dimensions and project requirements.

Pipe Hangers

Pipe hangers are used to suspend pipes from ceilings, beams, or other overhead structures, providing vertical support while enabling controlled motion. They are ideal for large-scale industrial facilities with extensive overhead piping.

At Precision Fabrication & Laser Cut, we have delivered custom pipe hangers for diverse sectors, including energy, construction, and utilities. Our hangers are fabricated to handle different pipe weights and dynamic loads.

Pipe Re-pads

Pipe re-pads are reinforcement pads welded around areas of pipes that contact supports, providing extra strength and preventing wear due to friction or movement. They are critical in extending pipe life in high-stress areas.

Our fabrication team has produced re-pads for heavy-duty industrial and petrochemical pipelines, ensuring maximum reinforcement where it matters most. We use precise cutting and welding techniques for durability.

Anchors

Pipe anchors are fixed supports designed to restrict the movement of pipes in specific directions, especially axial shifts caused by thermal expansion or system pressure. They are critical for maintaining pipeline alignment and preventing mechanical stress.

We’ve fabricated durable and custom-designed pipe anchors for complex pipelines in oil and gas facilities and manufacturing plants. Our anchors are built to meet industry standards for strength, reliability, and safety.

Dummy Legs

Dummy legs, also known as stub supports, provide stability to vertical piping, especially in tight spaces where traditional supports aren’t feasible. They help transfer pipe weight to nearby structural components.

We’ve fabricated dummy legs for a variety of industrial piping applications where space constraints and pipe configurations require innovative support solutions. Our designs are both practical and compliant with industry specifications.

Why Choose Us for Pipe Support Fabrication?

With over 15 years of experience, Precision Fabrication & Laser Cut delivers reliable, custom pipe support solutions built to meet industry demands. From pipe shoes to hangers and clamps, our certified team ensures precise fabrication, fast turnaround, and consistent quality.

We use advanced equipment, follow strict quality control, and work closely with clients across Alberta’s industrial sectors — delivering supports that perform under pressure.

Call us Today

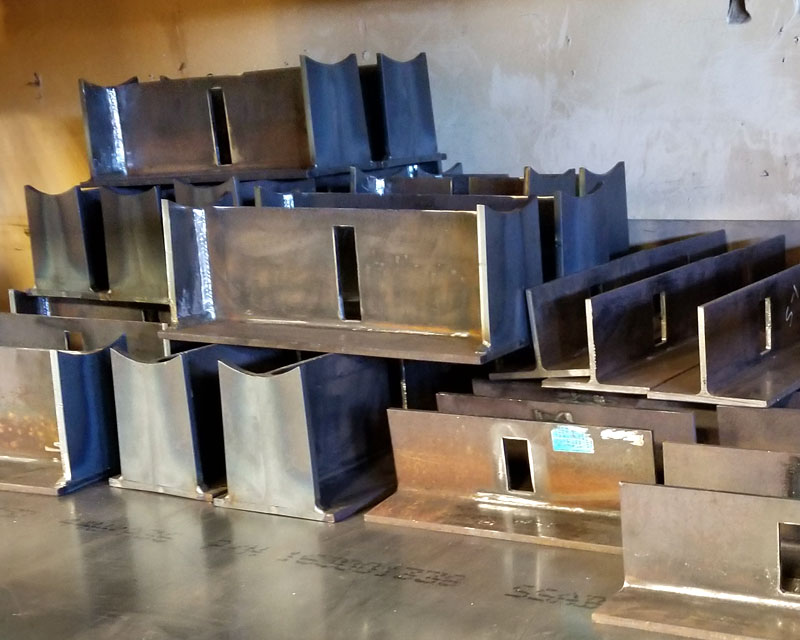

Pipe Support Project Gallery

We have completed pipe support fabrication for oil & gas, structural, infrastructure, water treatment, maintenance, and many other industrial sectors.

Frequently Asked Questions for Pipe Support

Pipe Support Fabrication involves designing and constructing support systems for pipes used in various industries. It ensures stability, alignment, and safety of piping systems by creating custom supports tailored to specific project requirements.

Proper pipe support is vital to maintain structural integrity, prevent pipe stress, and ensure operational safety. It prevents sagging, vibration, and misalignment, extending the lifespan of the piping system and reducing the risk of leaks or failures.

Pipe supports vary, including hangers, clamps, brackets, and rollers. Each type serves specific purposes, providing support against gravity, thermal expansion, contraction, or seismic activity based on the application and industry standards.

Custom pipe support addresses unique industry requirements by offering tailored solutions that consider factors like pipe material, size, weight, and environmental conditions. This customization ensures optimal support, enhancing efficiency, safety, and longevity within specific industrial applications.